Canadian Solar Topcon N-type PV modules

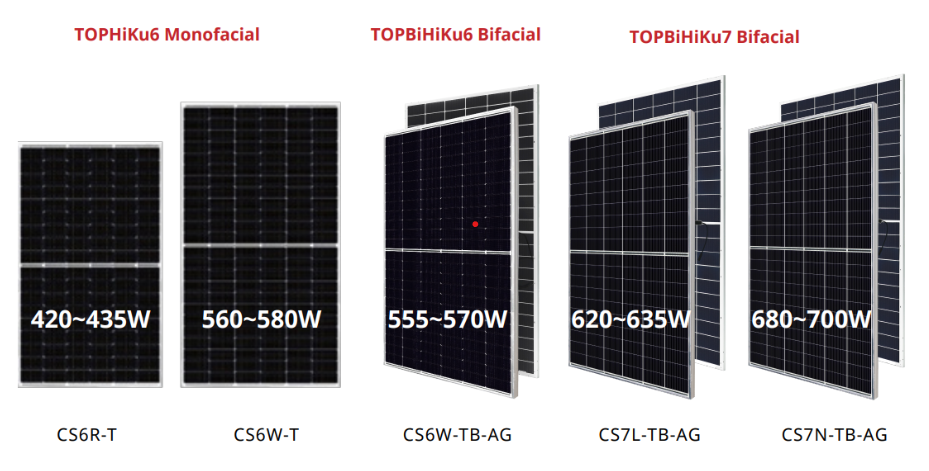

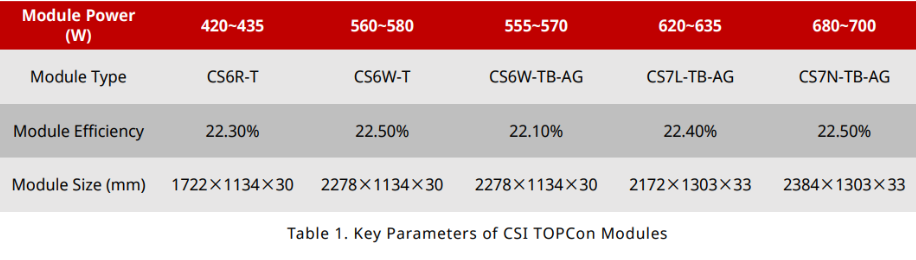

Canadian Solar was one of the first companies to introduce PV cell and module technologies that later became the industry mainstream, such as bifacial modules (back in 2010), modules with larger-format wafers (up to 210 mm) and, nowadays, N-type high-efficiency cells and modules. Since 2019, CSI Solar has been developing N-type TOPCon (Tunnel Oxide Passivated Contacts) technologies, and is now launching a diversified TOPCon module portfolio covering both 182 mm and 210 mm cells, single-glass and double-glass encapsulation, and various module sizes and power outputs to satisfy different application scenarios.

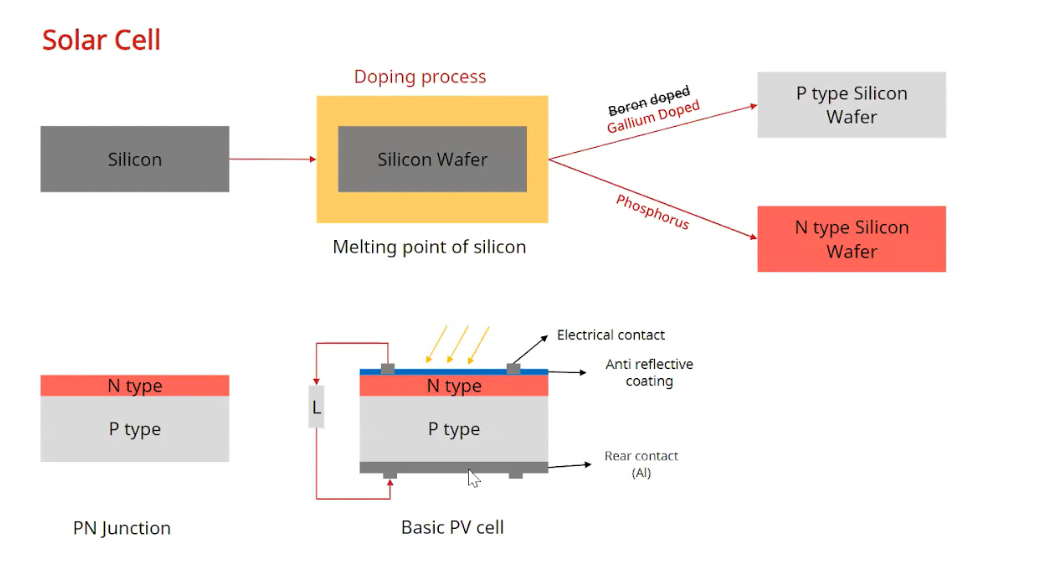

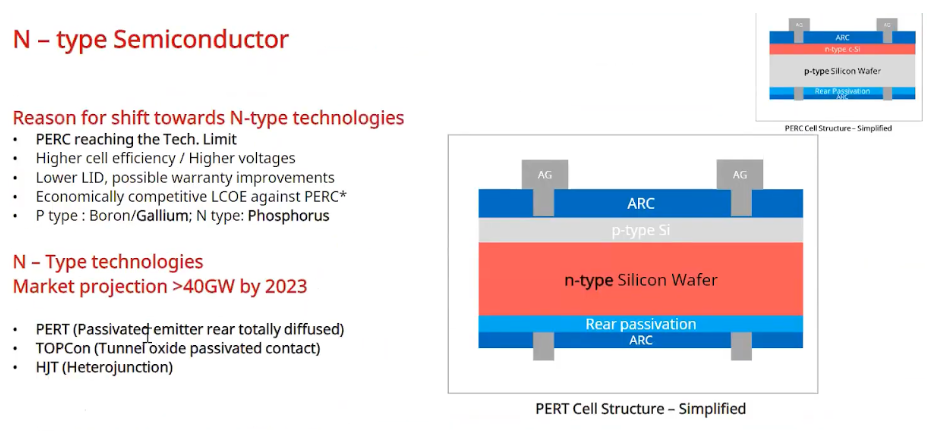

N-type solar cells have a slightly different construction compared to traditional p-type solar cells. The main difference lies in the doping of the semiconductor material used in the cell. Here is a general overview of the construction of an n-type solar cell: Substrate: The solar cell starts with a substrate, which is typically a thin wafer made of high-purity monocrystalline or multicrystalline silicon. N-type Dopant: The front side of the substrate is doped with an n-type dopant, such as phosphorus. This introduces extra electrons into the silicon lattice, creating an excess of negatively charged carriers. Anti-Reflective Coating: A thin layer of an anti-reflective coating, such as silicon nitride (SiNx), is deposited on the front surface of the cell. This coating reduces reflection losses and enhances light absorption. Front Metal Contacts: Metal contacts, typically made of silver or silver/aluminum paste, are applied to the front surface to collect the electrons generated when sunlight hits the cell. These contacts are arranged in a grid-like pattern to maximize the collection area. Passivation Layer: A passivation layer is applied to the front surface to reduce recombination of charge carriers. This layer is usually made of silicon oxide (SiOx) or a combination of silicon oxide and silicon nitride. Back Metal Contacts: On the back surface of the cell, a metal contact is applied to collect the positive charge carriers (holes) created during solar cell operation. This back contact can be a full-area aluminum layer or a patterned design. Back Surface Field: To further enhance cell performance, an additional layer known as the back surface field (BSF) may be included. This layer, usually made of heavily doped silicon, helps to create a gradient in the electric field, facilitating the efficient collection of charge carriers.

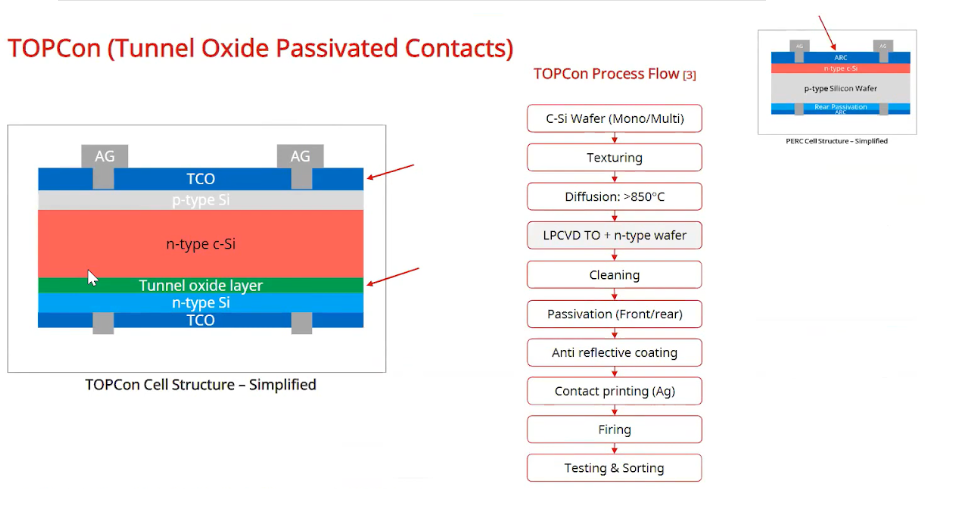

TopCon technology, on the other hand, utilizes a thin layer of silicon oxide to passivate the surfaces of the solar cell, reducing carrier recombination and improving overall efficiency. This technology helps to achieve higher energy conversion efficiency by minimizing energy losses.

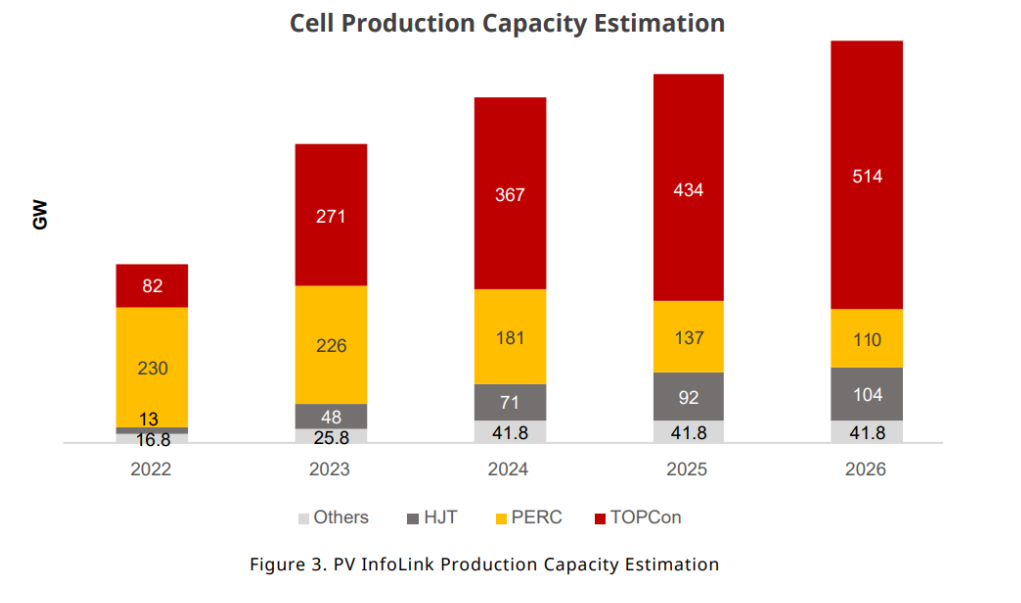

When combined with N-type silicon wafers, the upper efficiency limit of TOPCon cells is estimated to be 28.7%, outclassing that of PERC, which would be about 24.5%. TOPCon’s processing is more compatible to the existing PERC production lines, thus balancing better manufacturing cost and higher module efficiency. TOPCon is expected to be mainstream cell technology in the coming years.

Solar cell construction

It’s important to note that the actual construction details may vary among different manufacturers and specific cell designs. The above description provides a general outline of the construction process for n-type solar cells.

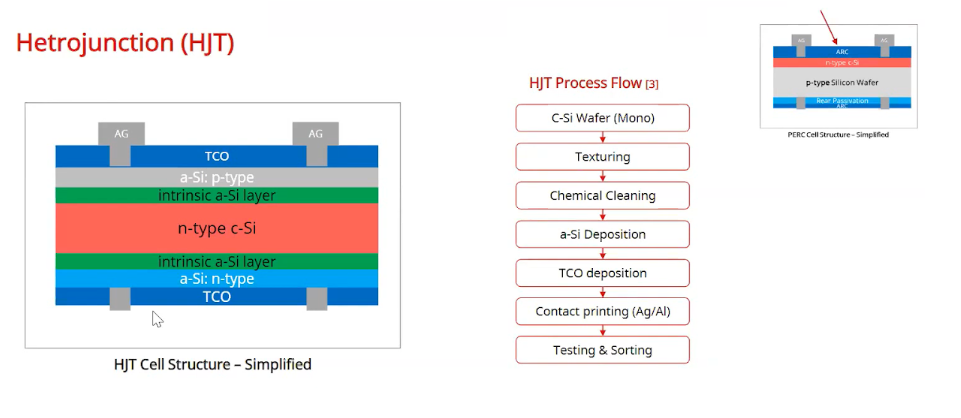

N-type Topcon and Hetrojunction PV cell structure

This lower cost and flexibility in the type of materials that amorphous silicon can be deposited on are a couple of important advantages. With heterojunction solar cells, a conventional crystalline silicon wafer has amorphous silicon deposited on its front and back surfaces. This results in a couple of layers of thin-film solar that absorb extra photons which would otherwise not get captured by the middle crystalline silicon wafer. The HJT production concept was developed by SANYO Electric in the 1980s (SANYO was acquired by Panasonic in 2009). SANYO was the first company to commercially produce solar cells made of amorphous silicon. Heterojunction solar technology takes advantage of this by building a solar panel out of three different layers of photovoltaic material.

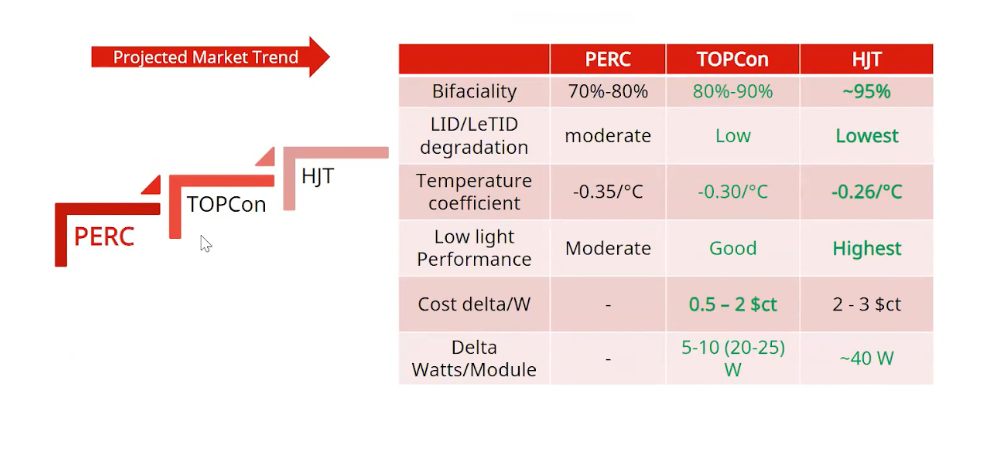

The top and bottom layer are made up of thin-film amorphous solar cells, the middle layer is a crystalline solar cell. The thin-film silicon on top captures some sunlight before it hits the crystalline layer, and it also grabs some sunlight that reflects off the layers below. It’s very thin, so much of the sunlight passes right through and the sunlight that passes through the middle, i.e the crystalline layer, is absorbed by the thin amorphous layer that is below. By building a panel out of a sandwich of three different photovoltaic layers, a heterojunction solar panel can reach efficiencies of 21% or higher. This is comparable to panels that use different technologies to achieve high performance.Comparison between PERC, Topcon and Hetrojunction modules

Subscribe to our newsletter

so that you don’t miss any news!