Jinko Solar Panel Technology

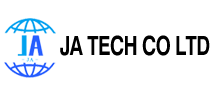

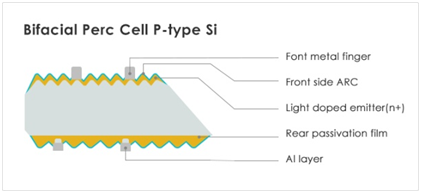

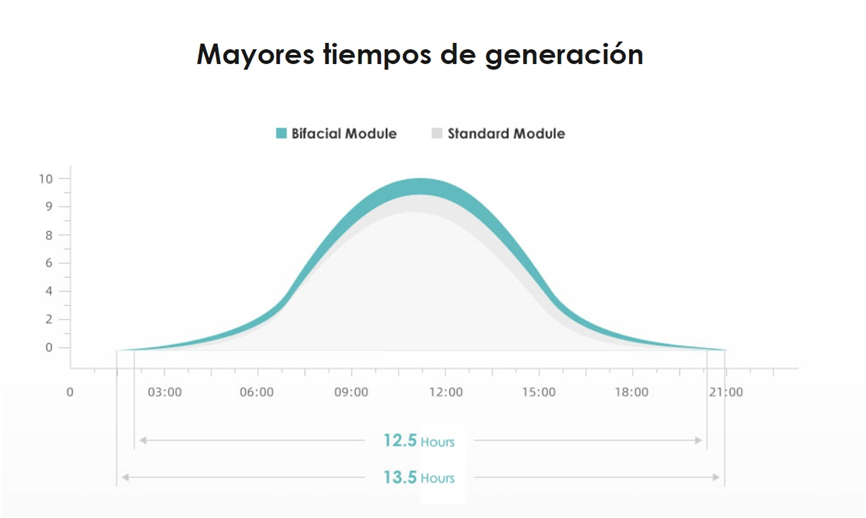

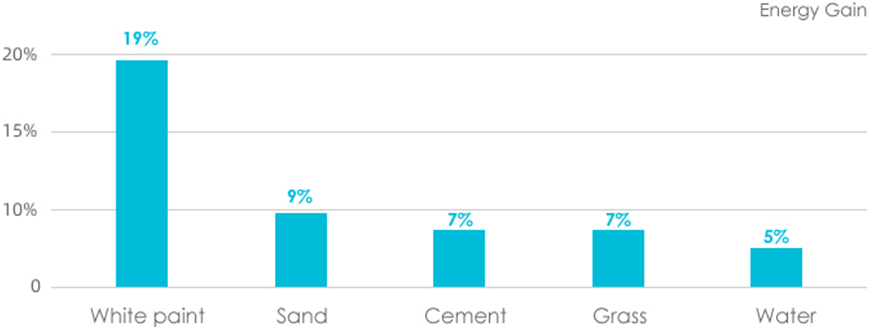

Jinko Solar Co.,Ltd is a globally renowned and highly innovative solar technology company. Embracing the mission of "optimizing the energy portfolio and taking responsibility for enabling a suitable future," the company strategically positions itself in the core segments of the photovoltaic industry chain. It focus on integrated research, delelopment, and manufacturing of photovolatic produts, as well as providing comprehensive clean energy solutions,leading in sales in the global mainstream photovoltaic market. Due to the huge demand for residential hybrid inverters, JA Solar considered adding a new manufacturer to its portfolio. After much research and analyses of local market requirements, a decision was made. The following criteria were taken into considerate. Half cells modules are created by cutting standard solar panels in half, resulting in 120 or 144 half-cut cells, while maintaining the same design and dimensions as conventional modules. Half-cut cells are typically produced using laser cutting technology. The standard solar cells are cut into two identical half-cells along the direction perpendicular to the main grid lines. These half-cells are then connected in series through welding. By utilizing half-cut cells, we can achieve higher module efficiency and improved performance.With half the current and double the voltage compared to standard modules, the electrical resistance remains unchanged. This means that we can generate more power while minimizing energy losses. Similar to conventional modules, half-cut cells are encapsulated using tempered glass, EVA, and a backsheet. This ensures durability and protection against external factors. Low Working Temperature Apple-to-Apple Temperature measured in R&D PV system in Oct.2017, Half-cell module is around ~2 degrees lower. Less Shading Loss Shading loss of half-cell is much better than normal module in certain shading conditions. High Output Power As the name implies, bifacial modules are modules that can generate electricity on both the front and back sides. When sunlight shines on a bifacial module, some of the light will be reflected by the surrounding environment to the back of the bifacial module. This part of the light can be absorbed by the battery, thus making a certain contribution to the photocurrent and efficiency of the battery. Longer power generation time More power generation gain Up to 20% power gain depending on albedo and PV system design.Half Cell Module Technology

Bifacial Module With Transparent Backsheet Technology

Subscribe to our newsletter

so that you don’t miss any news!